News

Best Crosscut Shredder for Secure Document Disposal

In an era where safeguarding your personal and business information is vital, using the right tools is key. At JustBinding, we understand the importance of protecting your documents from identity...

Read More

Binding Machines for Presentations: Your Ultimate Guide

At JustBinding, we understand that in the realm of professional presentations, making a strong first impression is crucial. Binding machines are essential tools that help turn loose sheets into organized,...

Read More

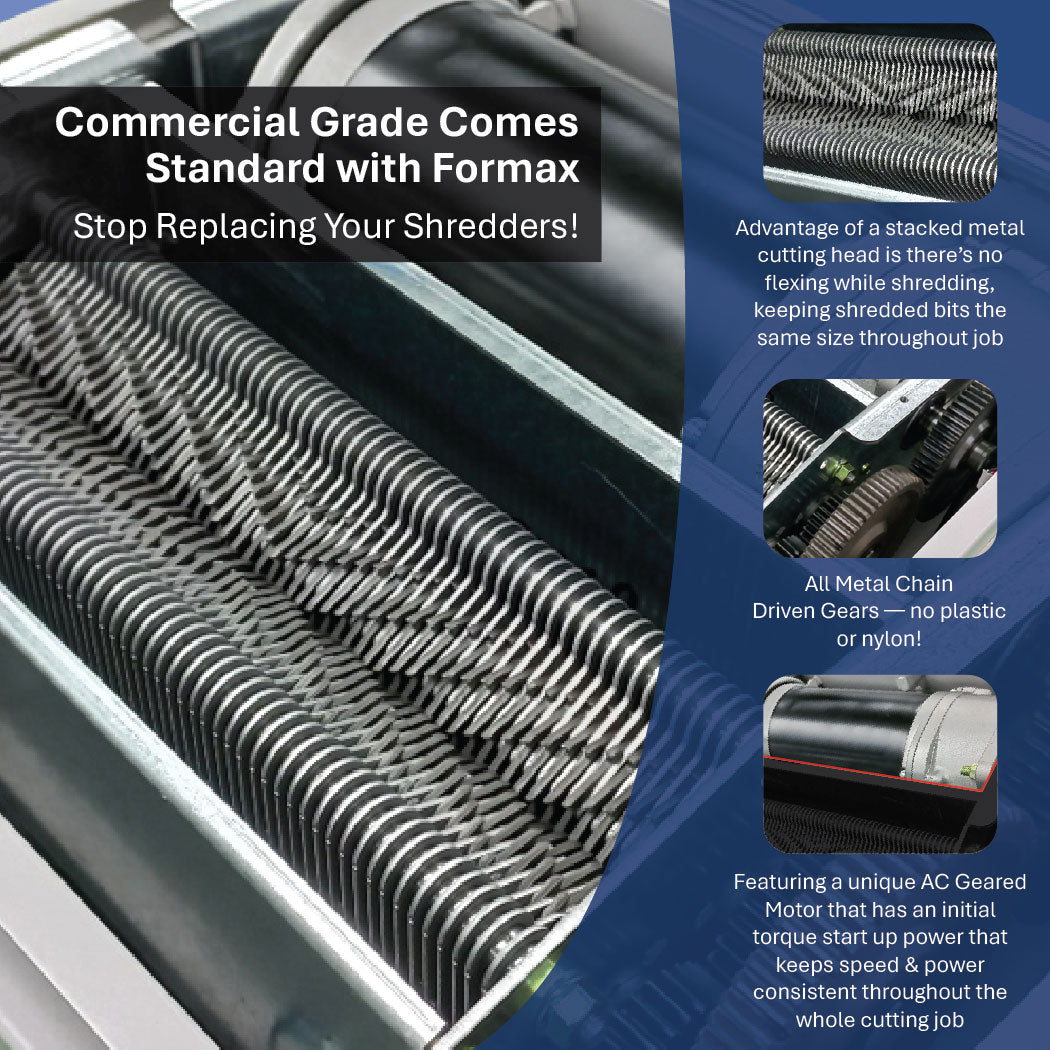

Shredder Heavy Duty Office: Best for Secure Document Destruction

Reliable Heavy-Duty Shredders for Your Office Needs - JustBinding In today's fast-paced business world, ensuring the secure destruction of documents is more important than ever. With sensitive information frequently circulating...

Read More

Best Laminator for Office: Top Lamination Machines & Materials

Discover the Best Laminator for Your Office Needs with JustBindingIn the hustle and bustle of today's office environments, having the right tools is crucial.

Read More

Best Heavy Duty Paper Shredder for Secure Office Use

Choose the Best Heavy Duty Paper Shredder for Your OfficeIn today's fast-paced office environment, keeping sensitive information secure is crucial. At JustBinding, we understand the importance of document shredding in...

Read More

Best Paper Shredders: High Capacity & Confidential Use

Best Paper Shredders: Your Office Guide - JustBindingIn today's fast-paced office settings, keeping your documents secure and organized is essential. Paper shredders are key to ensuring sensitive information stays confidential,...

Read More

Choose the Best Heavy Duty Paper Cutter for Precision Cuts

Find Your Perfect Heavy Duty Paper Cutter with JustBindingIn the world of professional document finishing, the right heavy duty paper cutter can transform your workflow.

Read More

Choosing Binding for Paper: Explore Book Binding Options

Choosing the Right Binding for Your Documents - JustBinding At JustBinding, we understand that selecting the right binding for your documents is crucial.

Read More

Best Paper Shredder for Small Business: Top Office Picks

Choosing the Best Paper Shredder for Small Business - JustBinding In today's fast-paced business world, keeping your documents secure and organized is crucial. For small businesses, investing in a dependable...

Read More

Boost Productivity with Essential Paper Cutters & More

Boost Productivity with Essential Paper Cutters from JustBinding In dynamic professional settings, efficiency is key. One tool that significantly enhances productivity is the paper cutter.

Read More